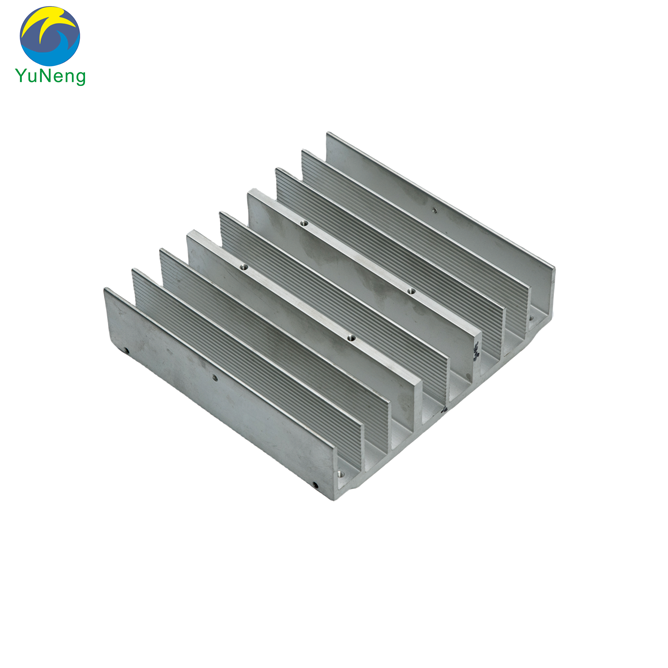

High Efficiency Heat sink

High Efficiency Heat sink is a critical component designed to efficiently dissipate heat generated by electronic devices and systems. Made from materials with high thermal conductivity, such as aluminum or copper, these Heat sinks are engineered to prevent overheating and maintain optimal performance of sensitive electronic components.

The high efficiency of these Heat sinks is achieved through advanced designs that maximize surface area and airflow. Features like fins, pins, or perforated patterns increase the heat dissipation surface, allowing for faster and more effective cooling. By improving airflow around the device, these heat sinks ensure that heat is rapidly transferred away from the electronic components, preventing thermal damage and ensuring long-term reliability.

High Efficiency Heat Sinks are commonly used in various applications, including LED lighting, power supplies, CPUs, GPUs, and industrial machinery. They are available in various sizes and configurations, including extruded, forged, and CNC-milled designs, to suit specific cooling needs and device shapes.

By effectively managing heat, these heat sinks contribute to enhanced performance, extended lifespan, and improved reliability of electronic devices, making them an essential component for both consumer electronics and industrial applications.

Features

Superior Heat Dissipation

Designed to quickly and effectively transfer heat away from electronic components, ensuring optimal performance and preventing overheating.

High Thermal Conductivity Materials

Made from materials with excellent thermal conductivity, such as aluminum and copper, which efficiently absorb and dissipate heat.

Optimized Design for Maximum Surface Area

Features like fins, pins, or perforated surfaces increase the surface area, allowing for improved airflow and faster heat transfer, which leads to more efficient cooling.

Lightweight yet Durable

Constructed from lightweight aluminum or high-strength copper, these heat sinks provide exceptional durability without adding unnecessary weight to the system.

Improved Airflow for Enhanced Cooling

The design is engineered to optimize airflow around the heat sink, increasing cooling efficiency and preventing heat buildup around sensitive components.

Application

1.Consumer Electronics

Devices: Smartphones, laptops, gaming consoles, and wearable devices.

Purpose: Prevent overheating of processors, GPUs, and power management circuits.

Benefit: Enhances device performance and extends lifespan by maintaining optimal operating temperatures.

2. Power Electronics

Devices: Power supplies, voltage regulators, inverters, and motor drives.

Purpose: Dissipate heat generated by high-power components to ensure stable operation.

Benefit: Improves efficiency and reliability of power electronic systems.

Wikipedia

ohmite.com

3. Automotive Electronics

Components: Engine control units (ECUs), battery management systems (BMS), and lighting modules.

Purpose: Manage heat in electronic systems within vehicles, especially in electric and hybrid models.

Benefit: Ensures longevity and performance of automotive electronic systems.

4. Industrial Equipment

Applications: Robotics, programmable logic controllers (PLCs), and industrial automation systems.

Purpose: Maintain thermal stability in environments with high operational demands.

Benefit: Reduces downtime and maintenance costs by preventing thermal-related failures.

5. Telecommunications

Devices: Base stations, routers, and network switches.

Purpose: Dissipate heat in densely packed electronic components.

Benefit: Enhances system reliability and data transmission efficiency.

FAQ

1.What materials are high efficiency heat sinks made from?

High efficiency heat sinks are typically made from materials with high thermal conductivity, such as aluminum and copper. Aluminum is the most commonly used material due to its light weight, corrosion resistance, and good thermal conductivity. Copper, while more efficient in heat dissipation, is heavier and more expensive.

2. How do I choose the right heat sink for my application?

Choosing the right heat sink depends on factors such as heat dissipation needs, available space, thermal resistance, and airflow conditions. For high power components, a larger surface area or active cooling solutions (like fans) might be necessary. Always consider the thermal design and device specifications when selecting a heat sink.

3. What are the benefits of using a high efficiency heat sink?

High efficiency heat sinks prevent overheating, ensuring optimal performance and extending the lifespan of electronic components. They reduce the need for active cooling, improve energy efficiency, and protect devices from thermal damage, leading to lower maintenance costs and higher system reliability.

4. Can high efficiency heat sinks be customized for my project?

Yes, many manufacturers offer custom heat sink designs tailored to specific applications. You can select parameters such as size, shape, material, and mounting options to meet your project's unique thermal management requirements.

5. What is the typical lifespan of a high efficiency heat sink?

The lifespan of a heat sink largely depends on the material and environment it is used in. Heat sinks made from aluminum or copper can last for decades, provided they are properly maintained and not exposed to harsh environmental factors like extreme temperatures or corrosive conditions.

Everything in the universe has a soul,everything happens for a reason.

Life is created by each step of ourselves,be kind and soft in each action include our thoughts.

Hand in hand we stand, together to prosper.